Introduction

Time is money—nowhere is this truer than in cnc with 4th axis machining. Machines that should be cutting parts are often sitting idle during setup, costing workshops thousands of dollars per month.

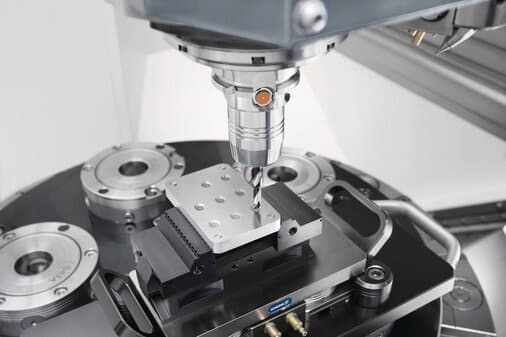

Enter the self-centering vise, a workholding innovation that reduces setup time by up to 50% or more, boosting productivity without adding new machines.

The True Cost of Setup Time

In a typical job shop:

- Each setup can take 15–20 minutes.

- With 20 setups per week, that’s 400 minutes—or nearly 7 hours—of lost machining time weekly.

- Over a year, that’s 350+ hours of idle machine time.

Multiply by machine hourly rates ($75–$200/hour), and the annual cost of inefficiency can exceed $50,000 per machine.

How Self-Centering Vises Slash Setup Time

- Automatic Alignment

- Traditional vises require measurement and adjustment.

- Self-centering vises align automatically to the centerline.

- Traditional vises require measurement and adjustment.

- Quick-Change Jaws

- Modular jaw systems allow instant switching between parts.

- Especially powerful in high-mix, low-volume production.

- Modular jaw systems allow instant switching between parts.

- Repeatability Across Operators

- No need to rely on “operator feel.”

- A new trainee can achieve the same setup speed as a veteran.

- No need to rely on “operator feel.”

Case Example: Small CNC Shop

A 15-machine shop in Texas reported:

- Setup time reduced from 18 minutes to 9 minutes per job.

- With 40 setups weekly, they saved ~6 hours/week.

- Annual savings: ~$45,000 in extra machining capacity.

Beyond Time Savings: The Compounding Benefits

- Higher Machine Utilization: More parts per shift without new equipment.

- Lower Labor Costs: Operators spend less time adjusting, more time supervising machines.

- Faster Delivery: Quicker turnaround means more competitive lead times.

- Employee Satisfaction: Less tedious setup work, fewer errors.

ROI Analysis

- Investment: $3,000–$6,000 per vise.

- Savings: Often $30,000–$50,000 annually per machine.

- Payback Period: 2–6 months.

Few investments in a machine shop offer such rapid and reliable returns.

Marketing Advantage

Workshops adopting self-centering vises gain more than fixturing clamps efficiency—they gain a selling point.

- “Fast turnaround times”

- “Reduced variability”

- “High flexibility for custom parts”

These differentiators help win bids in a competitive market.

Future Outlook

With the rise of Industry 4.0, expect setup efficiency to improve further as vises integrate with:

- Sensors for real-time alignment verification.

- Robotics for fully automated part loading.

- AI Scheduling Systems optimizing setup across multiple machines.

Conclusion

5th axis vises are more than tools—they’re time machines for workshops. By slashing setup time in half, they unlock capacity, reduce costs, and provide a clear competitive edge.

For operations managers seeking the fastest path to productivity gains, the answer is clear: reinvent your workholding, reinvent your efficiency.